| Project Scope and Objectives | |

|

|

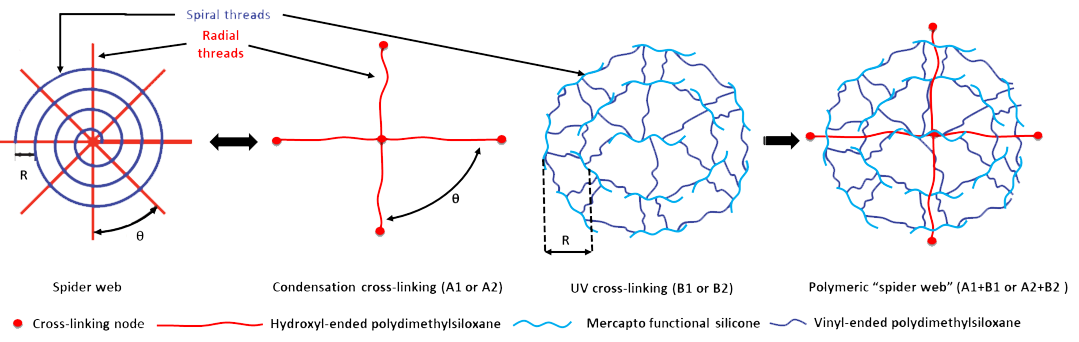

The main objective of the project is to use nature-inspired silicone-based IPNs to increase the yield strength and elongation at break of the final products based on remarkable architectures presented by spider webs [1] choosing the right similarities, as presented below. New approaches will be developed mainly consisting of obtaining new full interpenetrated polymer networks (IPNs) by choosing different cross-linking pathways: condensation route (Network A1 or A2) and UV thiol-ene cross-linking (Network B1 or B2). Moreover, the nature of these two approaches allowed green approaches to obtain silicone-based IPNs by means of synthesis and thin elastomer preparation. Condensation route (that takes place between hydroxyl-terminated PDMSs) will ensure the radial threads with a variable θ angle by choosing different cross-linking agent (trifunctional or multi-functional; thus a small angle is obtained) and varying the molecular mass will toiler the mechanical properties. UV thiol-ene cross-linking (that takes place between a multifunctional copolymer with pendant -SH groups and vinyl terminated PDMS) will ensure the spiral threads with a variable R distance obtained by different vinyl terminated PDMS having several molecular weights. In order to achieve the projects main objective (MO), secondary objectives (SO) will be implemented as follows: SO1 – Obtaining green silicone-based IPNs (TRL 2 and 3); the originality is to develop new green non-polar IPNs by interpenetrating a network cured by condensation route (network A1) and another one by UV thiol-ene cross-linking (network B1), aiming to study the influence of several parameters (e.g. θ angle, R distribution) upon the final properties on the “polymeric webs” and testing as single layer variable capacitors as PTO on laboratory-made set-up that simulates OWC conditions (e.g. inflation, frequency). SO2 – Obtaining polar silicone-based IPNs (TRL 2 and 3); the originality is to develop new green polar IPNs by interpenetrating a polar network cured by condensation route (network A2) and another polar one by UV thiol-ene cross-linking (network B2), aiming to study the influence of several parameters (e.g. θ angle, R distribution) upon the final properties on the “polymeric webs” and testing as single layer variable capacitors as PTO on laboratory-made set-up that simulates OWC conditions (e.g. inflation, frequency). SO3 – Testing the chosen materials from SO1 and SO2 on a simulated real environmental set-up (TRL 4). SO4 - Dissemination and Project Management.

1. [Cranford, S. W.; Tarakanova, A.; Pugno, N. M.; Buehler, M. J. Nonlinear Material Behaviour of Spider Silk Yields Robust Webs. Nature 2012, 482 (7383), 72–76]

Spider web architecture and similarities associated with the polymeric networks